A complete guide to LIDAR: What is it and how to build it

Unlocking a world of possibilities, LIDAR has emerged as a groundbreaking sensing device that forever transforms our understanding and interaction with the environment.

But what exactly is LIDAR, and how does it work?

Diving into its origins and comparing it to RADAR, we uncover the remarkable capabilities of this technology and explore its wide-ranging applications.

Read on!

Understanding LIDAR: A revolutionary sensing device

Have you ever wondered how we gather valuable information about our environment? Enter LIDAR, a cutting-edge sensing device that has revolutionized the way we perceive and interact with the world around us. But what exactly is LIDAR, and how does it work?

LIDAR, short for Light Detection and Ranging, is also often called laser RADAR (Radio Detection and Ranging). But although both LIDAR and RADAR are used for object detection, their underlying technologies and methods differ significantly.

Now, before we dive into the specifics, let’s see first how LIDAR came to be.

➥ LIDAR origins

We can track back the origins of LIDAR to the emergence of lasers in 1961. Hughes Aircraft Company was the first to develop a LIDAR-like device, combining a laser with imaging optics to measure the distance of an object by calculating the time it takes for the laser signal to travel to and from the target.

Originally named COLIDAR (Coherent Light Detecting and Ranging), this technology was primarily used for satellite tracking. LIDAR’s early applications also extended to meteorology, aiding in cloud and air pollution detection.

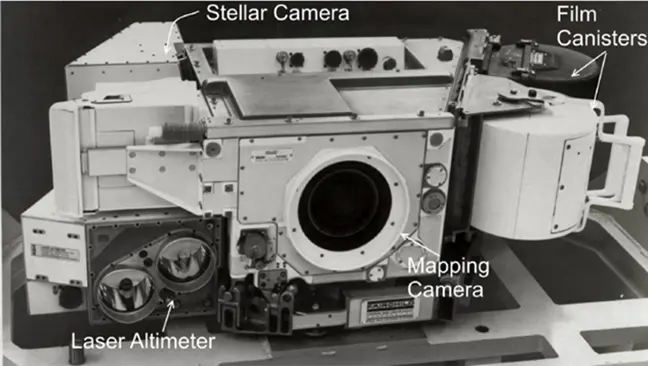

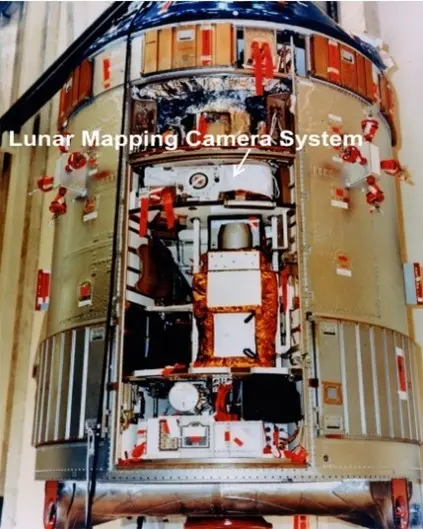

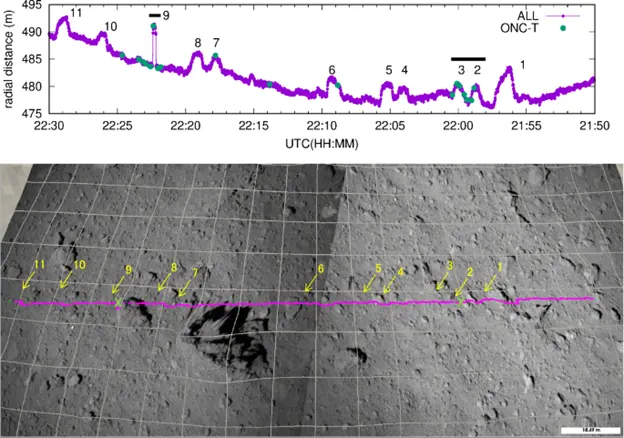

It wasn’t until 1971 that LIDAR gained wider recognition when astronauts on the Apollo 15 mission used a laser altimeter to measure the spacecraft’s altitude over the moon’s surface. This pivotal moment brought LIDAR into the public eye, capturing imaginations with its remarkable capabilities.

➥ Detecting the objects: LIDAR vs. RADAR

So, how does LIDAR detect objects and determine their position? Let’s break it down and compare it to RADAR.

The LIDAR device emits a laser pulse towards an object, which then reflects part of the pulse back to the sensor. By measuring the time it takes for the pulse to return, the LIDAR calculates the object’s position using a method known as time-of-flight.

Unlike RADAR, which uses radio waves (1-100 cm) for detection, LIDAR employs electromagnetic (EM) waves in the ultraviolet (UV) to infrared (IR) wavelength spectrum (250 nm – 10 µm).

There are a few other notable differences between LIDAR and RADAR.

For instance, LIDAR employs cameras, photodiodes, or other imaging sensors to detect the returned signal, whereas RADAR relies on antennas. This disparity leads to variations in their range and precision. LIDAR provides highly accurate measurements at close range, while RADAR excels in scanning larger areas rapidly, albeit with lower precision. Additionally, LIDAR requires a clear line of sight to the detected object, whereas RADAR can penetrate obstacles such as fog and rain.

➥ Main applications of LIDAR

These distinctions between LIDAR and RADAR dictate their respective use cases, as well.

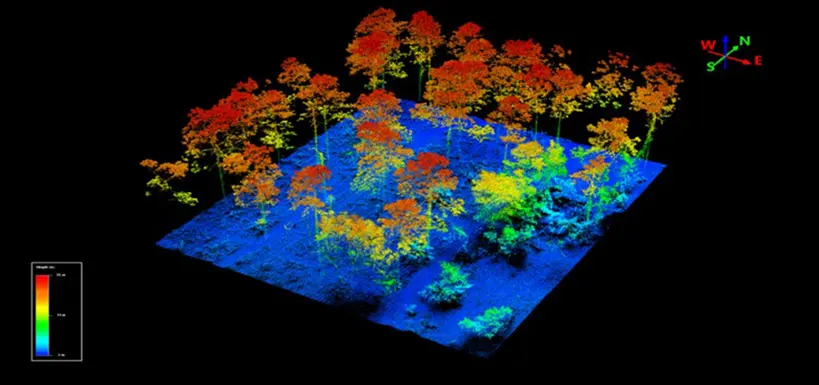

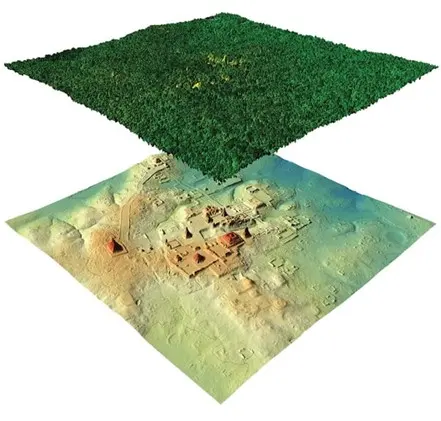

LIDAR is commonly used for mapping and surveying, generating detailed 3D maps of the surrounding environment. When combined with GPS data and inertial measurements, the recorded data forms a point cloud, a precise representation of the scanned area.

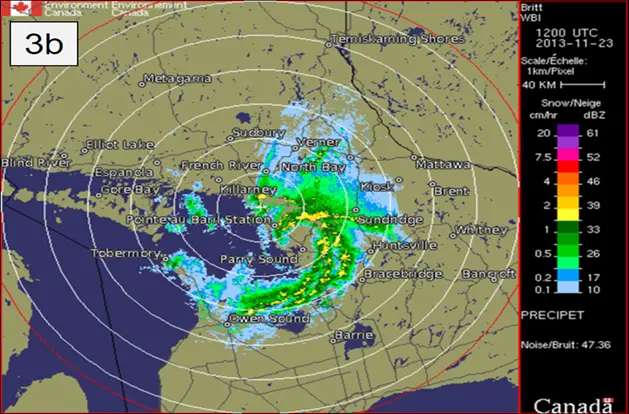

In contrast, RADAR commonly produces 2D images that provide information about the size, shape, and distance of objects.

Now that we understand the main differences between LIDAR and RADAR, here are some of the incredible applications of LIDAR technology:

- Detection of atmospheric turbulence in airplanes

- Environmental monitoring and research, including gas and particle concentration detection, wind measurement, and temperature sensing

- Optimization of wind turbine farms

- Security surveillance

- Obstacle detection in robotics

- Geodesy, geology, forestry, agriculture, and archaeology

- Fusion research facilities in physics

- Laser altimetry in satellite orbiting missions

- Enhancing video games and augmented reality experiences

- Object and obstacle detection in the automotive industry

The versatility of LIDAR technology makes it a powerful tool in various fields, revolutionizing how we interact with and understand our world. As technology continues to evolve, we can expect even more groundbreaking applications to emerge, pushing the boundaries of what is possible with LIDAR.

Building a LIDAR: Main components and construction process

To build a LIDAR system, you need quite a lot of components working in harmony. The main components include:

- Laser

- Detector and scanning system

- Global positioning system (GPS)

- Inertia measurement unit (IMU)

- Timing electronics

1. Laser

LIDAR systems can be classified into two types: coherent and incoherent systems. Each type uses a specific laser, which plays a crucial role in their operation.

- In incoherent systems, Q-switched pulsed lasers with a pulse width of around 10 ns are the most common. These lasers produce peak powers ranging from several hundred watts, depending on the wavelength employed.

- On the other hand, coherent systems employ single-frequency lasers that generate a linearly up-chirped light signal, requiring lower power due to their more sensitive detection method.

Choosing the appropriate laser wavelength is another critical consideration in LIDAR construction.

Typically, LIDAR systems use lasers with wavelengths ranging from the ultraviolet (UV) to the infrared (IR) spectrum. In non-scientific applications, the most common wavelength falls within the range of 600-1000 nm. Laser diodes around 905 nm are the most frequent choice due to their affordability and ability to operate in pulsed mode.

An alternative wavelength is 1550 nm, which is eye-safe at higher power levels and remains invisible in night vision goggles. That is also why they’re very common in military applications. However, lasers at 1550 nm face two major challenges:

- They are strongly absorbed by water, which makes them unsuitable for certain conditions.

- Detector technology is less advanced, which leads to increased costs and reduced sensitivity.

For specific LIDAR applications, there are more complex laser systems that use frequency doubling or tripling available, and they are most common for scientific or underwater research purposes.

2. Scanning system

An optics and scanning system directs the laser beam towards objects in the environment. Typically, two sets of telescopes are employed – one to shape the output laser beam and another to detect the returning beam efficiently.

This scanning optics part is built using at least two high-reflectivity mirrors optimized for the laser’s specific wavelength. Using this setup with two mirrors, it is usually possible to cover the whole solid angle around the LIDAR, while using only one mirror wouldn’t cover the whole space.

We can control the mirrors using galvanometers, electric motors, piezoelectric actuators, or magnetostrictive actuators. Alternatively, we can also use microelectromechanical (MEMS) mirrors. Depending on the technology used to move the mirrors, different angular velocities and ranges can be achieved. Additionally, instead of the scanning optics, a LIDAR can have a pre-aligned optics setup where the entire sensor rotates to detect objects within a wider field of view.

Furthermore, there are several different sensors that we can use to collect the returning light in a LIDAR system. Photodiodes are the most common for light collection, while photon-counting photomultipliers or avalanche photodiodes are ideal when we require higher sensitivity. Alternatively, cameras with high quantum efficiency – such as CMOS, CCD, or EMCCD chips – can serve as light-detecting sensors.

3. GPS and IMU

To precisely determine the location of objects within the environment, LIDAR systems incorporate Global Positioning Systems (GPS) and Inertia Measurement Units (IMU).

The GPS sensor provides the precise position of the LIDAR sensor in Cartesian coordinates (x, y, z). The IMU, on the other hand, has an accelerometer, magnetometer, and gyroscope sensors, which provide accurate velocity and orientation measurements. And ultimately, the GPS and IMU combined enable LIDAR systems to geolocate detected objects precisely.

4. Timing electronics

Last but certainly not least, the timing electronics play a vital role in LIDAR systems. As object positioning relies on accurate time measurement, the precision of a LIDAR is directly related to the quality of its timing electronics.

This unit measures time on scales ranging from hundreds of picoseconds (10-10 s) to several microseconds (10-6 s). This requires stable references, which clocks based on crystals can provide. However, for applications requiring even higher precision, we can employ ultra-stable references like Rubidium or Cesium atomic clock units.

How does LIDAR know where an object is?

When a LIDAR emits a laser pulse, its internal clock begins ticking. The pulse travels to an object, scatters upon impact, and a portion of it returns to the LIDAR detector. This prompts the clock to stop, and the elapsed time becomes the key factor in calculating the distance from the detected object.

And the formula for calculating this object distance in LIDAR is quite simple:

d = (c · t) / 2

The c represents the speed of light (approximately 3×108 m/s), t is the time elapsed from pulse emission to detection, and d is the distance from the detected object. We call this method of determining the object distance time-of-flight.

Now, let’s see how this works in the two types of LIDAR systems.

➥ Incoherent LIDAR systems

Incoherent LIDAR systems detect the energy (or power) of scattered pulses from an object directly. By conducting multiple measurements as described earlier and scanning the laser beam’s direction, these systems collect information about objects in the environment, ultimately forming a point cloud.

Incoherent LIDAR commonly employs pulsed lasers with nanosecond pulse durations. But the energy of these pulses has to be quite high to provide a detectable scattered signal. And since this scattered signal is usually very weak, photodetectors have to be highly sensitive and very fast.

Examples of such photodetectors are avalanche photodiodes and single photon detectors. They both operate on a similar principle where only a few photons trigger an avalanche of electrons within the detector, enabling accurate measurement of the electric signal.

➥ Coherent LIDAR systems

The second type is coherent LIDAR. Its main distinction from incoherent LIDAR lies in the detection principle.

In coherent LIDAR, the scattered signal from an object is detected using optical heterodyne detection. This method involves mixing the scattered signal with a local oscillator, significantly enhancing sensitivity. A local oscillator is a portion of the output laser beam that is split before it leaves the LIDAR.

Another significant difference lies in the usage of single-frequency laser light with a linear up-chirp. This means that the laser’s frequency is swept across a range of frequencies. With time, the frequency difference between the scattered signal and the local oscillator increases, so the information about the distance of the detected object is obtained by measuring the beat-note signal.

The accuracy within a specific range is determined by the sweep period, so to achieve the best range accuracy, alternating sweep periods are used to achieve the best range accuracy.

Coherent LIDAR uses single-frequency lasers (in contrast to pulsed lasers used in incoherent LIDAR), with low-power diode lasers being the most common choice.

Another crucial component is the frequency sweep control, which must be carefully tailored and very precise. Detectors in coherent LIDAR are relatively straightforward, often utilizing standard photodiodes since the beat-note signal tends to be strong.

Additionally, there’s one major advantage to coherent LIDAR – the ability to detect the longitudinal velocity of moving objects relative to the LIDAR, thanks to the Doppler effect.

How is LIDAR used in the automotive industry?

Within the automotive industry, we can use many different sensors to increase the security of all traffic participants. Among these sensors are cameras, proximity sensors, RADAR, LIDAR, and many more.

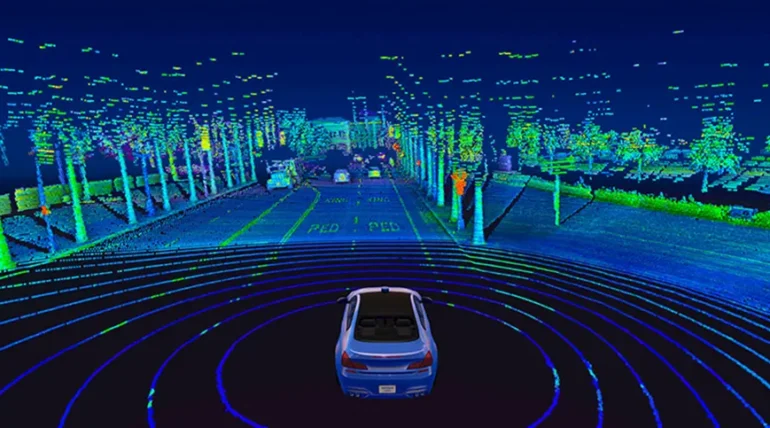

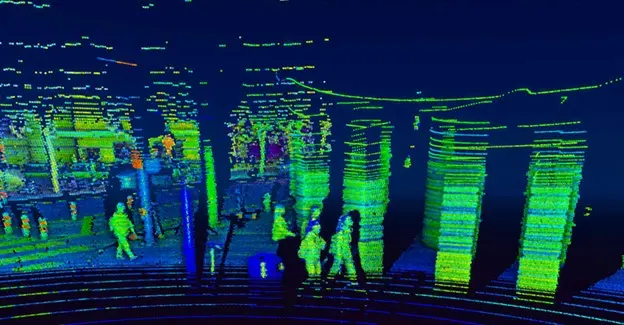

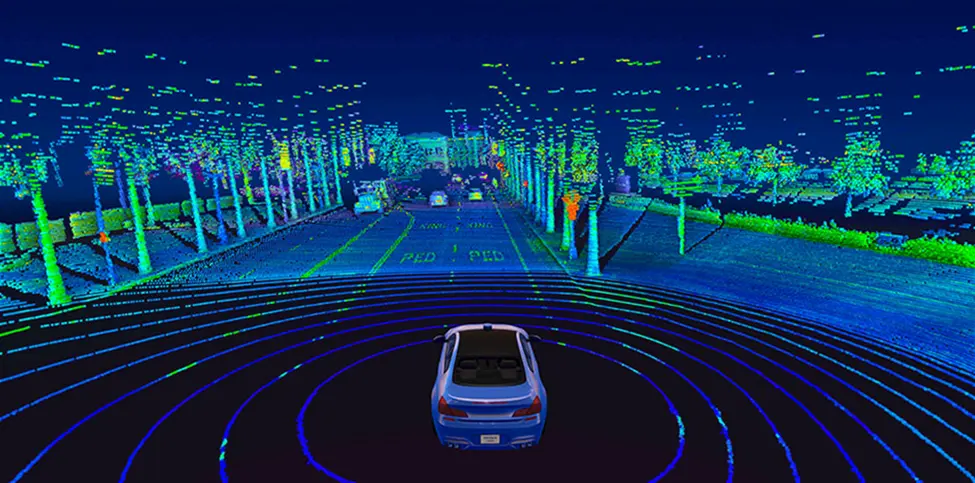

While cameras provide a 2D image, making it challenging to get precise 3D information about objects, LIDAR emerges as a game-changing technology. It provides a detailed 3D image of the car’s surroundings in real time, which makes LIDAR a vital sensor in vehicles, especially for autonomous vehicles and Advanced Driver Assistance Systems (ADAS).

An example of one such LIDAR sensor is Velodyne HDL-64e. Equipped with 64 lasers mounted on its base and just as many avalanche photodetectors to receive scattered laser pulses, this sensor emits pulses approximately 10 ns wide at a wavelength of 905 nm.

With a rotation speed ranging from 300 to 900 RPM (or 5 to 15 Hz), it emits pulses 4,000 times per revolution. By employing the time-of-flight method to measure the distance from objects, this sensor delivers a staggering data rate of around 1.3 Mpx per second in the form of a point cloud. It effectively measures distances within a full 360-degree field of view and covers approximately 27 degrees in the vertical field of view.

It’s worth noting that other LIDAR sensors used in ADAS may exhibit distinct characteristics, such as a limited field of view, different number of lasers used, rotation speeds, and more.

You can see an example of a point cloud recorded from a LIDAR mounted on a car in the photo above. Additionally, the video below provides a real-time recording of a point cloud.

A significant advantage of LIDAR is its ability to see objects in low-light conditions, such as during the night or under overcast skies, surpassing the capabilities of camera-based solutions. This, in conjunction with the information outlined in this section, establishes LIDAR as a superior sensor when compared to camera systems in terms of measuring the depth and distance from objects, as well as in low light conditions.

It’s important to note that this does not diminish the value of data collected from cameras; rather, the combination of LIDAR and cameras presents a supreme solution for cutting-edge ADAS and autonomous vehicles.

All in all, by incorporating LIDAR technology, the automotive industry gains an unprecedented level of insight into the surrounding environment, elevating safety measures and propelling advancements in autonomous driving and ADAS.

Interested in autonomous driving?

Get in touch with us to learn more about our technology or to join our team!